Natural LDPE is very flexible and translucent in appearance. It’s a soft, flexible, lightweight plastic material, noted for its low temperature flexibility, toughness, and corrosion resistance. This allows the consumer to have a greater experience in seeing the contents and product level as well as holding and squeezing the packaging.

In comparison, it is more malleable than high density polyethylene (HDPE), especially popular with customers looking to have squeezy packaging.

Please note: it is important to check the compatibility of your product due to the low-density nature of the polyethylene or to seek expert advice. Generally, it is not suited for applications where stiffness, high temperature resistance and structural strength are required.

What is LDPE plastic used for?

LDPE is used for manufacturing various containers, dispensing and squeeze bottles, tubing, plastic parts of computer components, moulded laboratory equipment and many caps and closures. It is robust enough to be almost unbreakable.

It’s most common use is in plastic bags for food shopping and also in the dry cleaning plastic covers that protect your newly cleaned clothes.

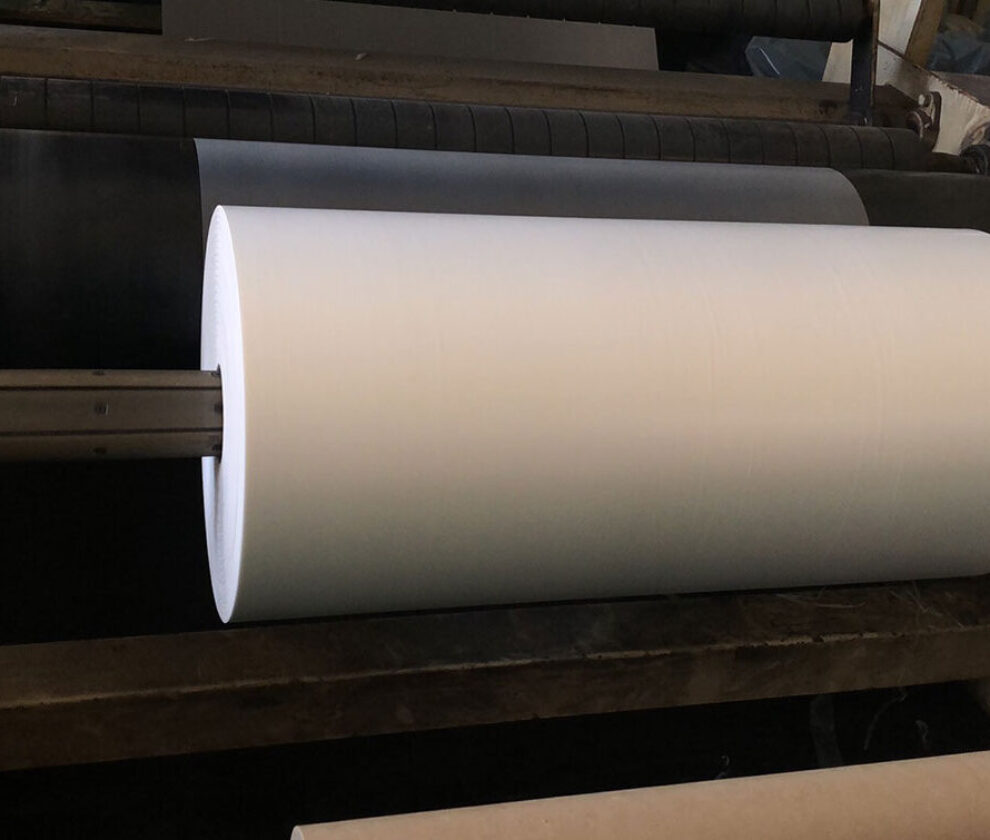

Commercially, it’s mainly used as plastic film and packaging to protect a number of products, using it’s tough, flexible and transparent qualities.

LDPE Plastic Recycling Process

During the recycling process, used LDPE is chopped up into small pieces and then formed into pellets. These pellets can then be turned into a variety of products and may have a small amount of virgin LDPE added to improve tensile strength and reliability. Many recycled LDPE products will be black in colour as it’s easier to turn clear plastic black, hence the use in bin liners, agricultural film, irrigation pipes, floor tiles and furniture.

Processing LDPE is one of the easiest plastics to work with. It offers the potential for injection, film and blow moulding and options to make resulting plastic material that is anti-slip, anti-static, anti-bacterial and flame retardant. The challenge for the recycling facility will be to clean and decontaminate the collected plastic packaging in an efficient way.